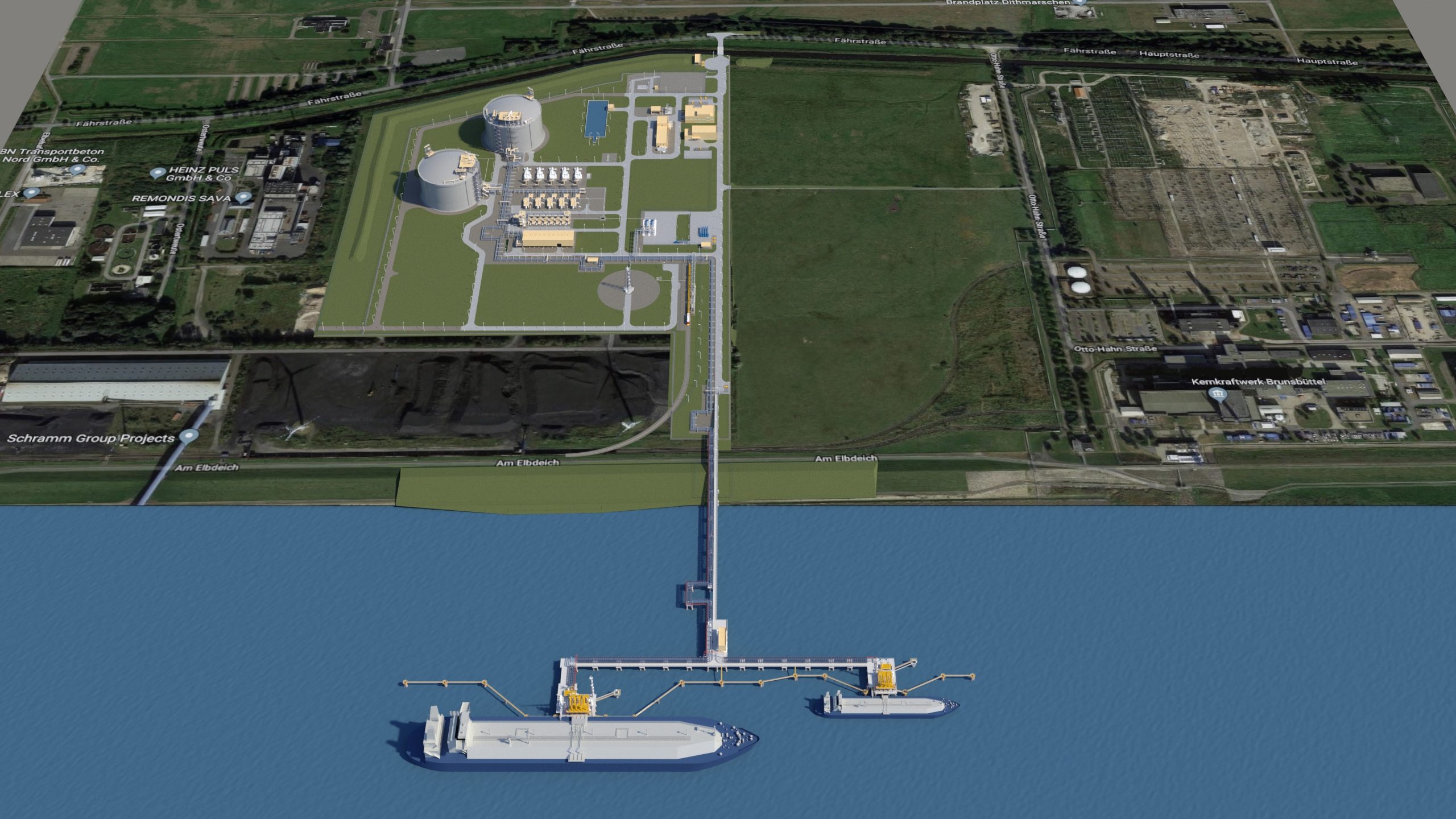

The “turnkey” project to realize Gate terminal, a Liquefied Natural Gas (LNG) terminal, which SENER and TECHINT are carrying out in Rotterdam (the Netherlands) as part of the TSEV consortium, has reached two million hours of construction work without any lost time incidents. The improvement of existing safety systems, thanks also to the introduction of a recent method called ‘(A)live on Site’, has yielded one of the best safety records achieved to date for work performed on the Rotterdam Europoort.

The “turnkey” project to realize Gate terminal, a Liquefied Natural Gas (LNG) terminal, which Sener and TECHINT are carrying out in Rotterdam (the Netherlands) as part of the TSEV consortium, has reached two million hours of construction work without any lost time incidents. The improvement of existing safety systems, thanks also to the introduction of a recent method called ‘(A)live on Site’, has yielded one of the best safety records achieved to date for work performed on the Rotterdam Europoort.

Gate terminal, which will be ready for operation in the second half of 2011, is one of the leading energy projects in the Netherlands and a technological showcase on European scale.

Within the TSEV consortium, made up of the Joint Venture TSLNG, in turn made up of Sener and TECHINT, and the sub-consortium EV (made up of the companies Entrepose and Vinci), Sener is responsible for managing the implementation and commissioning of the plant, as well as for basic engineering and most of the detail engineering of the project. In turn, TECHINT, besides consortium leadership, is responsible for part of the engineering, procurement and construction management.

Located on the Maasvlakte, in the Rotterdam area, Gate terminal will initially include three 180,000-m3/h storage tanks, with capacity for exporting 12 BCMA (Billion Cubic Metres per Annum) of natural gas, plus an extra 20% during consumption peaks. In any case, the plant is designed and prepared to allow a maximum expansion of up to 16 BCMA + 20% peak which includes a fourth LNG tank. It will have two Jetties, an unloading area, a storage and pumping area, the gasification and delivery area, auxiliary services and the complex of buildings (offices, control, security, workshops, etc.) required for the operation.

As pointed out by Guido Piazzoli, TSEV Project Director, the strong commitment of the whole Consortium management towards safety has allowed to reach such an important achievement. TS LNG Project Manager, Roberto Felipe, highlighted that Gate Terminal has been designed in accordance with four major aspects: safety, environment, availability and flexibility of the operation.

As regards security and the environment, the plant is designed to comply with the European regulation EN–1473 on onshore natural gas facilities. An innovative aspect is the preference the contract gives to the use of European regulations over any others, for example American. The design of the plant also complies with the demands imposed by the Dutch authorities and applicable local regulations. Furthermore, it includes the effluent management and control systems required to ensure the levels of solid, liquid and gaseous emissions remain well below the legal limits defined in the EIA (Environmental Impact Assessment) at all times.

About us

About us About us / section

About us / section Markets

Markets Markets / section

Markets / section Projects

Projects Careers

Careers Careers / section

Careers / section